Hello everybody!

I have finally made a new version of my mechapress88 (see my previous post here https://www.reddit.com/r/ErgoMechKeyboards/comments/1fs4ui9/we_need_more_flat_keyboards_meet_the_mechapress88/ ). This is the V3! I only assembled one half of the V2 and given up because it was too hard to assemble, so no post for that.

This keyboard uses the new Kailh PG1316S with actuation force of 35gf, as opposed to the Cherry ULP switches of the V1. To my knowledge, this is the first design to integrate RGB leds. Not that I find them useful, but it was more for the challenge :P Also, it features a speaker!

Now let's talk about the build.

Switches

As said before, the switches are the new Kailh PG1316S. The V1 had Cherry ULP switches which are of similar design. The mechapress v2 had all components on a single side, including the switches, the RGB leds and the diodes. This design only has the RGB leds under the switches, and the diodes on the underside.

I found that the Kailh switches are of poorer quality than the Cherry ULP. The main issue I have with them (which I discovered only after assembling the first half of the v2, and one half of the v3) is that around 10% of them do not lay flat on the board surface. Since I solder with a reflow oven, I place all the switches on the board and bake it. So it's only after taking the board out that I notice that 3-4 switches that are half soldered. This is an issue I didn't have with the v1 and the Cherry ULP, despite that being the first time I did such a job.

For the last half that I soldered, I only took good switches that lay flat on the board, and they all worked on first try.

Keycaps

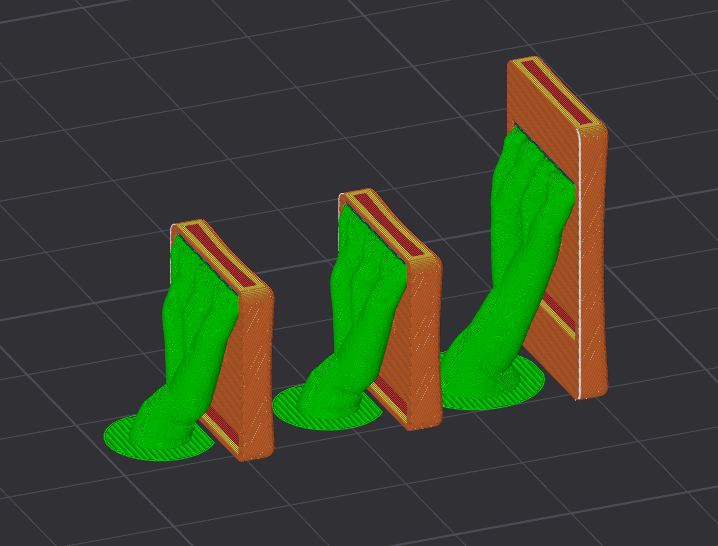

I didn't like the official keycaps, I wanted more opaque ones to diffuse the RGB light a bit, and a more concave design to better feel how fingers are placed on the keys (and I wanted a home row bump). I designed my own keycaps, https://cad.onshape.com/documents/a1e8f687f2876977978d0499/w/2031da5aa86fb49b49b9da68/e/8571dbe03717cd2187e32d4a (based on madbadmax's design from https://www.reddit.com/r/ErgoMechKeyboards/comments/zpo9h6/comment/j0ttss7/ ).

My keycaps are 3d-printed vertically with a single support, on a Voron Trident with a Revo 0.15mm nozzle.

After nailing down the tolerances, I managed to make something that works, but the feel of key presses is not great. If I want proper keycaps, I'll need to figure out how to access a resin 3d printer.

The Kailh switches are VERY fragile. Removing keycaps from them can easily damage them. For the last half, to remove the keycaps without damage, I baked it in my reflow oven. A few minutes at 80°C (which the maximum storage temperature indicated on the datasheet of the switches), then I took them out with tweezers. The board would cool down, so I had to bake it a few times.

Soldering

As other people have said it, soldering these switches is hard. Even more so when you have components under the switches. My mechapress v2 design had SOD-923 diodes, they are next to impossible to solder. They are tiny, The pads are tiny, the solder paste doesn't stick on such tiny pads, the diode doesn't either, I had to rework a lot of them.

For the v3, I switched to SOD-523 diodes, and put them underside so that I can fix them without removing the switch if need be. These diodes are almost impossible to solder. Even if they are bigger, they are still very small. Also putting components under the board makes reworking very hard. My solder plate was not in contact with the board, but with the diodes, so heat wouldn't propagate well through the board.

These are the v3's SOD-523 diodes.

So, for the v3, I used a reflow oven (the great Controleo v3), with SAC305 solder for the diodes, then reflowed a second time with low temp solder paste Sn42/Bi57/Ag1 for the top side. The use of low temp solder paste made reworking the board easier (especially for those bent switches!). Heating the hotplate to 200°C is enough melt the solder, though on the v3 with the diodes under, I had to heat it up to 220°C. I'm sure this helped not damage the diodes. Nevertheless, reworking the boards with a hot plate bends them. My right board isn't flat anymore.

Btw, stenciling was done with a personal fork of this jig https://github.com/scheffield/stencil-fix connected to a Dyson vacuum cleaner. Reworking was done with a MHP30 hot plate and a Pinecil solder iron.

I used a Pixel Pump ( https://shop.robins-tools.com/ ) to place the SMD components. It helped, but it's not miraculous. Placing SOD-923 or even SOD-523 diodes with it is still very hard. A few of them went flying and I didn't find them to this day.

Disclaimer: I have no electronics formation. I suck at this, and it may explain why I had such a hard time. Maybe I did things wrong too. I'm open to recommendations!

Case

The case is 3d printed. I finished designing it yesterday, to print today. Then, before going to bed, I saw the mikecinq post by @dynam1keNL ( https://www.reddit.com/r/ErgoMechKeyboards/comments/1kjbfr5/mikecinq_my_second_pg1316s_keyboard_incl_long/ ), and thought about slanting the top surface of my design too so that it doesn't get in the way of the thumb keys, and here it is!

The case is designed with build123d, a CAD tool that allows designing parts in Python (I guess that's nerd).

Controller

The same pro-micro clone from aliexpress that I used for the v1. Still running the qmk firmware.

Future build

This keyboard is still a prototype, features I plan to add:

- Make it easier to solder

- Wireless

- Aluminum case

- Keep ultra low profile design as much as possible

- Transporting case

- Open source

Closing thoughts

I hope you like this board!

I want to thank everyone who post their builds. They're a great inspiration, and I learned a lot from them. Please keep posting your custom builds. And to people who haven't attempted a build yet, please do it, the journey is long, but it is great :D

Photos are not of top quality, but neither is the keyboard, so I guess it's fine :D

Interesting but this seems like the least ergonomic keyboard possible

The voyager is very similar. I tried it flat and tented. I find that if I use it without the tenting attachments, it gets uncomfortable pretty quickly.

Amazing build though.