this post was submitted on 23 May 2025

9 points (100.0% liked)

Unfinished Proje

124 readers

13 users here now

This is the graveyard of unfinished proje

the holy land of unwholely leet

This is a place for your vibrant work of progre...

Glory to the unshared,

to the dreams turned embarras...

To the moldy napkin thot,

that plant you forgot;

this is a place for spins, (when it shouldn't),

When the glass half full is a leak

any kind of un can be proje

If #todo you finish,

erors u fix,

proje you complet

GOOD 4U!

#todo write rules about not being an ass 4 code of conduct

(moderation policy light and invisible, you see something - flag it, this is your community first - a mod is just the lazy janit...

founded 9 months ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

Spray glue maybe?

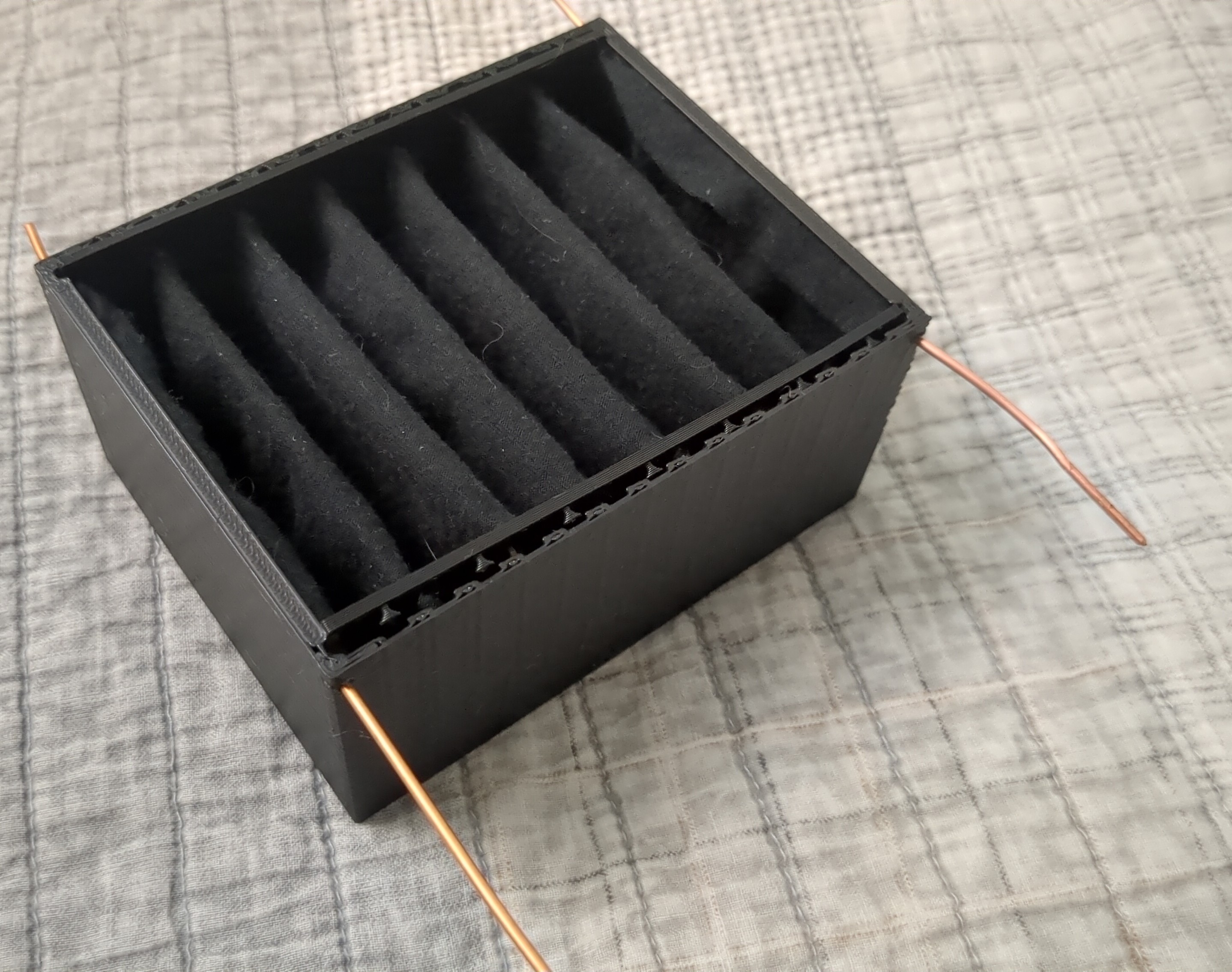

Adhesives are how most mass produced filters appear to be made. Creating an assembly is surprisingly complex. It is not easy to fold the pleats evenly AND get them taut in two directions.

One cool side effect is that any mechanical assembly would likely relate to the automated machinery and mechanisms that are needed to build a pleated filter with adhesives.

I wouldn't spray anything around an air filter medium like this. I would do stuff like dipping an edge into an adhesive and apply that edge to a frame. Then let this cure before further forming operations.

I also wonder about a layer on top of the media perhaps

You'd be making a K&N style filter then. It requires two sets of pleated fine mesh, with 5-8 layers of medical gauss formed between the mesh. Fabric doesn't conform well in a mesh like this. I have tried it before. The gauss has enough loose conformity to work, but it lacks the higher thread count of most textile fabrics and usually requires some kind of oil on the gauss to attract smaller particles without passing most of them.