Wait till you get older and your fine motor skills get sketchy.

I'm 57. The designer I do the soldering jobs for is in his early 80s. He can't do SMDs so I do all of that for him. He can still do THT components just fine but his designs have gotten more advanced and he just can't fit everything on the boards using THT.

I’m 35 and already feeling that :S

We have to adopt, I started working on old tube radios. Soldering spots 10 times the iron tip 😁

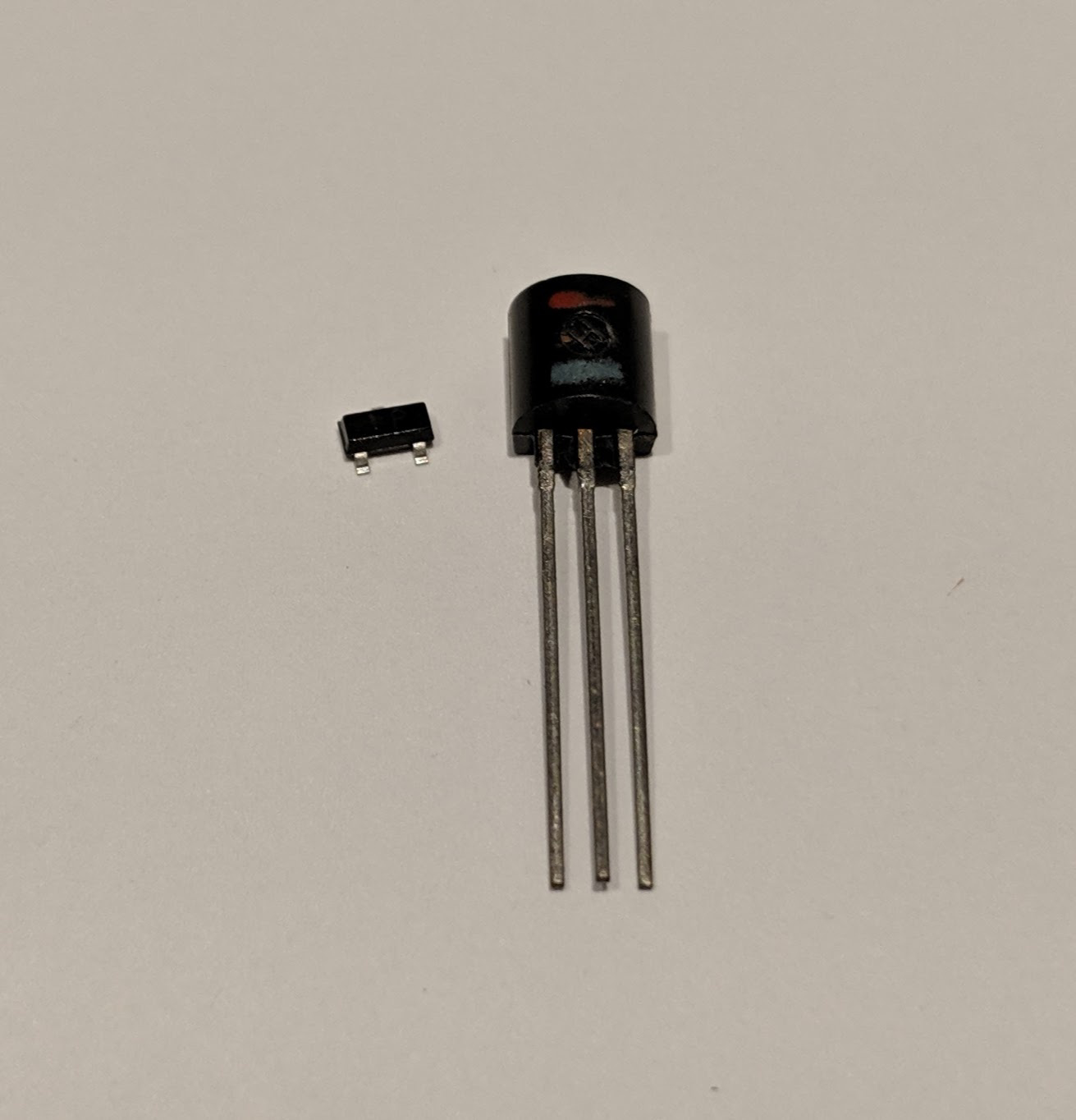

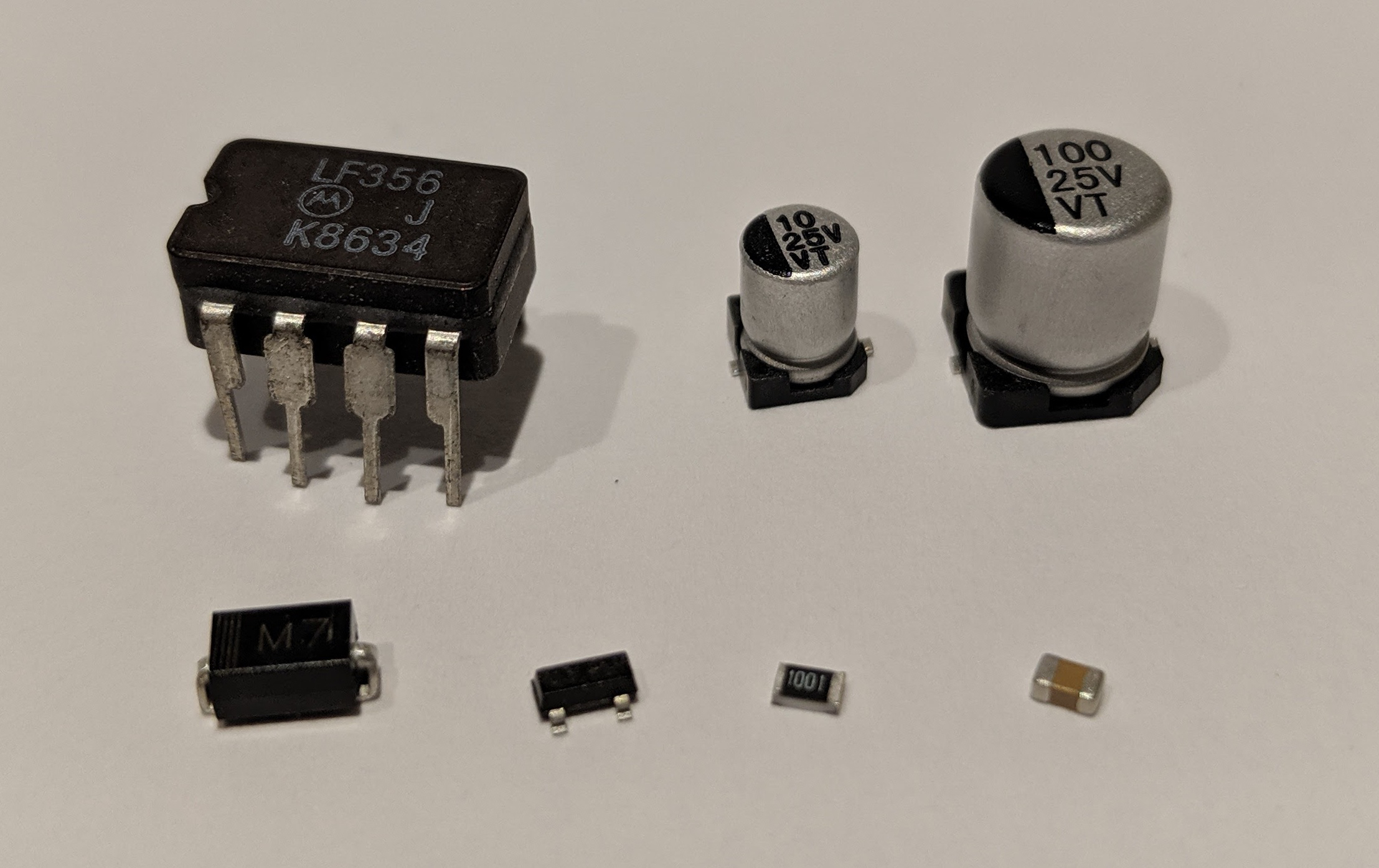

Wow things really have shrunk. I want to get into electronics to make guitar effect pedals, eventually. This looks really hard, kudos to you for working with such small parts.

I took a quick look and there are some DIY guitar pedal kits for around $35 on Amazon. They're probably not the best quality but they're definitely a way to get your feet wet.

The small parts are a challenge but the key part if getting them positioned properly and tacked down. Once you've got a couple of opposite pins you can work on the others easily. For the tiniest of pieces like the tiny resistors the surface tension of the solder will stand them right up on end and pull them around which is very frustrating. I get those in place, hit them with liquid flux, then hold them down and touch one end. After that the other end is easy.

What's important here is that I'm using a standard soldering iron like anyone would use. It's a good one but it's just a soldering iron.

That's the whole joy of audio that supposed to mess with the signal - it doesn't need high fidelity, high quality, it just needs to do something 'interesting'. The main thing that stops me is a lack of space to set up a mini-workshop. Thanks for the good explanation, I would have never imagined components wanting to do that! The last time I messed with electronics probably was Radio Shack kids kits in the 1980s, the kind where the board had springs sticking out and held resistors and diodes to build AM radios and things with lamps & switches. It'd be good to get into it, but it all seems so hard, complex, and advanced now. I mean Auduino is kinda cool, but it's too much like my day job so I want to go all-analogue. It doesn't stop me wanting to buy an oscilloscope though, just to see what's going on! I think part of that is trust that I'm not going to melt my favourite guitar amp...

What do you think of my new distortion pedal?

It's so...distorted.

I know, right? It's AWESOME!

I'm fortunate that I have a little straw bale shed behind my house where I have my office. It's 7' x 11' on the inside and I have 4' x 7' of one end walled off to form my office and the rest a front room with a futon couch. It is a tiny space but I fit a LOT into it. All you really need is a bin with a piece of hardboard in it to use as a table protector, your soldering iron, and other goodies. You can start small.

I bought a digital scope a while ago. It's a Siglent SDS 1102CML+. I think it's 100 MHz but it's software hackable up to...300 MHz? If you're going to be doing analog why not buy a used analog scope. I often see HPs and Tectronics on Facebook Marketplace for a couple of hundred dollars. Those are VERY nice scopes and, between you and me, it's a LOT more scope for the same money as the new digital scopes.

The SMD parts you've got there are still of the beefy and chunky variety. Have you had a look at some modern boards with microscopic capacitors and resistors nowaday? Have you had to "handle" a 01005 yet?

The smallest I have worked with are 0402s and I find them incredibly annoying. The smallest I go now is 0805. If I need smaller I'll just have the boards assembled by the fab house in China. I mostly use All PCB but my friends have tried PCB Way and another that I can't remember. They say that the boards are all basically the same.

This reminds me of high school. I took an electronics course and we had to hand etch our boards with tape and acid.

Oh man, I remember doing that. We had rub on transfer traces and pads that we could apply to the board before etching that did a good job. I used to buy those at Radio Shack.

My friends, the ones I take in the microscopic soldering jobs for, have a small CNC mill that they can use to mill boards. That's very cool.

I miss radio shack ! Yeah 2003 baby hah. I wish I could do microscopic soldering

I bought a Olympus SZ40 on an arm for $200 from a microscope shop in Montreal. It's the best $200 I've ever spent. It makes soldering so much easier.

I just do minor soldering with building ham radio antennas and power connectors. For the most part it's easy stuff but every now and then I build a small, low power antenna matching unit and holy cow...

Things get silly at really small sizes.

It is, though the process did start ages ago. The SNES from 1990 already had all the chips and most capacitors as SMDs, and the 1996 N64 motherboard is with the exception of the power LED entirely surface mount. I'd guess the reason for the recent disappearance of through hole devices is to with development of cheaper pick and place machines and labour cost increases - it's finally cheaper to get one of those to use with SMD components than it is to hire a warehouse full of labour to hand assemble your cheap thing from THD parts.

Also 0402 is an annoying SMD size code, as it's one of the two (other being 0603) that exist in both imperial and metric sizes - it can be 0402 metric, i.e 0.4mm x 0.2mm which is 01005 imperial, or 0402 imperial which is 1005 (1.0mm x 0.5mm) metric.

I've wanted to learn to solder for some time but it really does feel so precise and I have a bit of an issue with precision instruments for some reason (born that way no clue why).

Soldering is attainable for most people even with basic equipment. Most of us started with a basic consumer pencil iron. I still have the Weller WESD-51 that I used for more than 20 years sitting on my desk. My hope is that this group will provide support for beginners and allow more experienced hobbyists and professionals to talk about more advanced topics and techniques.

Maybe we need some short soldering 101 type videos?

I appreciate your giving me some good stuff to look up! Maybe I’ll actually take a real crack at it this time

I'm happy to give advice. I started out as a pre-teen leaning on my own. If there's something in particular that you want to know or see ask and I'll answer your questions or make up a quick video and stick it on YouTube.

Thank you so much! I guess the obvious question for me is: what should I attempt first to get comfortable with the process? I’m very comfortable doing tear downs of electronics at present but not soldering, which is the next step for what I want to do. Lots of retro console tinkering and repairing.

I still have an actual solder gun I inherited from my dad. It works great, but there's not much I can use it for now unless I take up wood burning.

Those things were awesome. My wife found one of Facebook Marketplace and sent me a link to the ad. I was like, "What they heck am I going to use that for?!?" She just laughed.

I end up needing a bunch of extras for 0102 components. If I don’t get contact with the solder blob before relaxing my grip on the tweezers, hot air blasts them away into oblivion.

Just commenting to say that I love the fact that this discussion/community randomly popped up in my feed. SMD soldering gives me the heebie-jeebies

Welcome. It's more of a challenge than soldering THT, that's for sure, but it can be done even with basic equipment. I'm going to Walmart tomorrow to buy a $10 soldering iron and I'm going to remake the SMD soldering videos on my YouTube channel using that $10 iron to show that it can be done. No one should be afraid of soldering SMDs.

Your photo really brings it home! Such a difference.

Yup. The thing that's important to remember is that everything in my photos can be hand soldered with a bit of knowledge. I have always used a fairly basic soldering iron or station. My videos are intended to show that it is possible with basic equipment.

Can I get a link to your channel?

I'm going to need more ideas to keep all these subscribers entertained.

Ive been having my fair share of troubles woth 0402s at work after I ripped all of the smd test point pads off woth oscilloscope probes. I ended up with a ton of wires kapton taped to the board and poked into a 0402 joint, and miscellaneous circuits deadbugged and built up with point to point wires. My favorite was bending tbe legs on a sot-6 up to hold a resistor and cap, and the top half the the voltage divider was floating in the air over the board

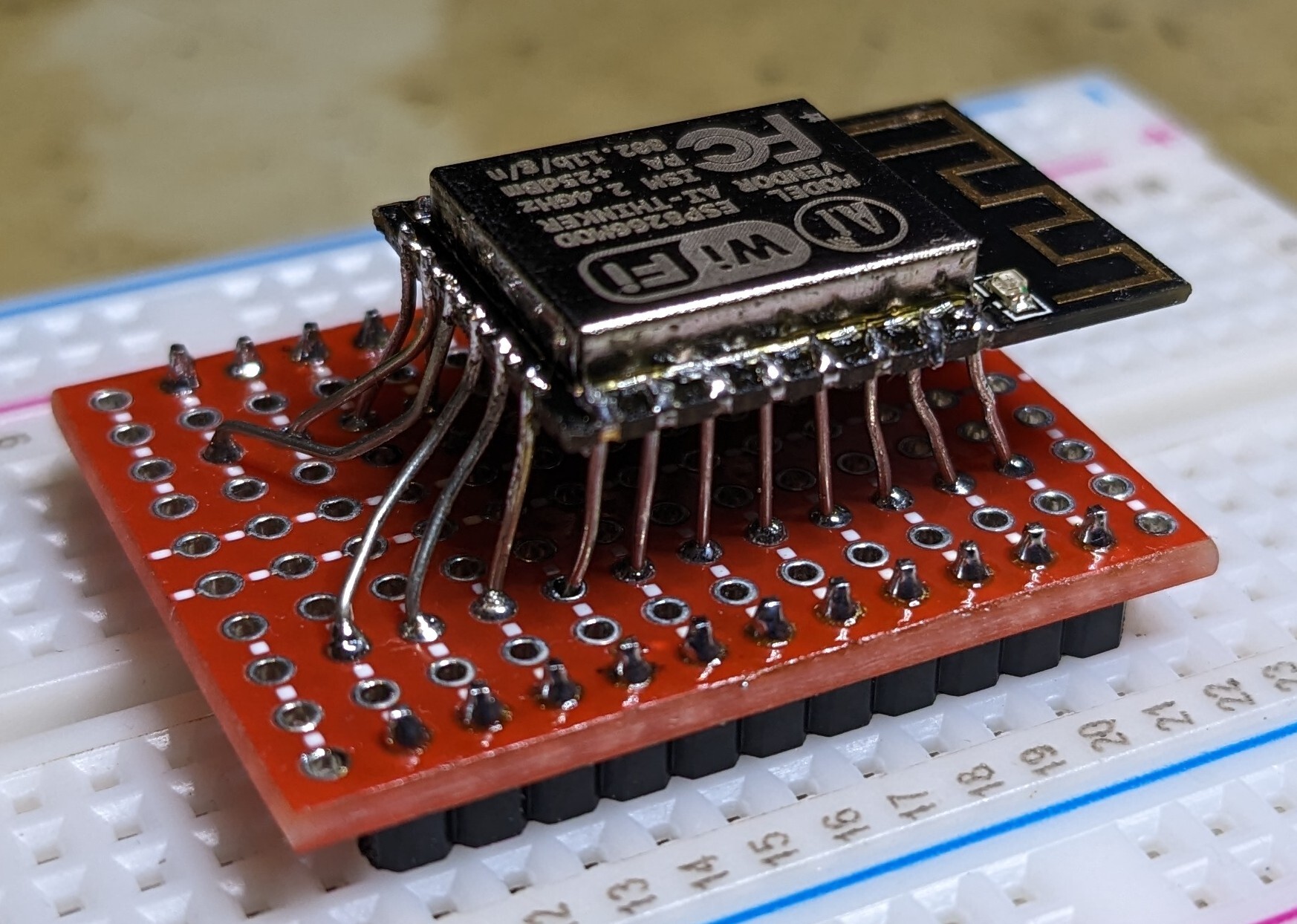

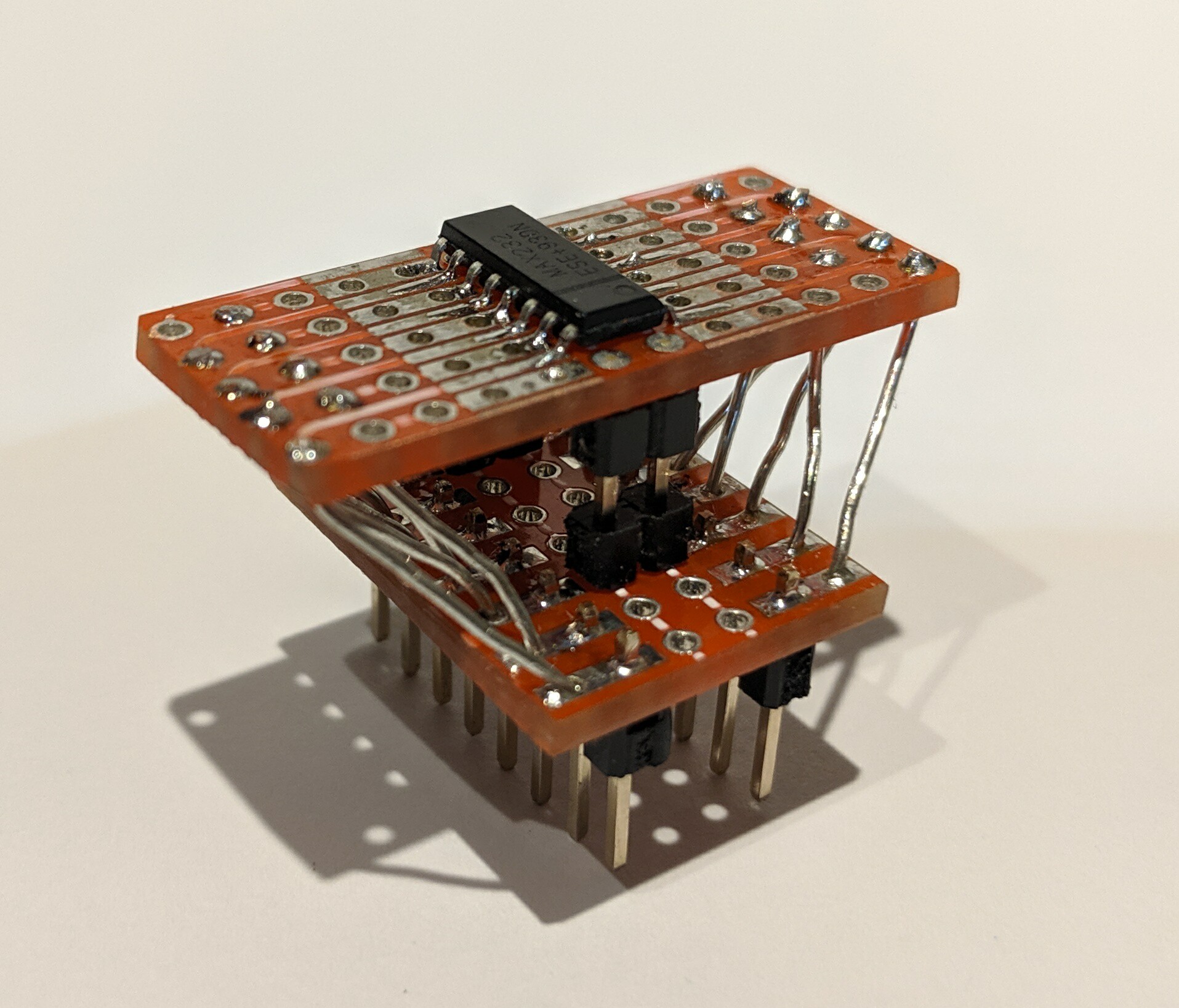

Adventures in soldering. Are you prototyping or are these production systems. I have one that I built a while ago that I'm not proud of but it works.

Hehehe. When I was looking for that one I found this monstrocity.

I had run out of adapter boards for the SOIC chip. I have a new stock of them now.

Tweezers tip irons and/or a hot air unit saves some of the headache. Now if only the ol' eye balls functioned like they used to back in the day... maybe the eyes where always bad and the writing on the through holes was just bigger haha!

Soldering

This community is for electronic hobbyists to discuss projects and is focused on soldering. Everyone is welcome from the noob to people who have been soldering as a hobby for decades to people who solder professionally. We'll talk about materials and techniques, equipment, and projects. Everyone is welcome. All questions are welcome. Post photos and ask for help.

RULES:

-

All Lemmy.ca rules apply here.

-

Everyone (see rule 98) is welcome.

-

If you’ve seen a question 100 times answer it the 101st time or ignore it. Even better, write a complete, detailed answer and suggest that the mod(s) pin it to the community.

[Did you actually think there were 98 rules?]

-

If you present something as fact and are asked to provide proof or a source provide proof or a source. Proof must be from a reliable source. If you fail to provide proof or a source your post or comment may be removed.

-

Don’t be a dick. Yes, this is a catch-all rule.

-

The mod(s) have the final say.