3D Printing

5047 readers

1 users here now

For everyhting 3D printing related.

Please be excellent to each other :)

Icon by Freepik, Banner photo by Thiago Medeiros Araujo

founded 4 years ago

MODERATORS

26

27

28

29

34

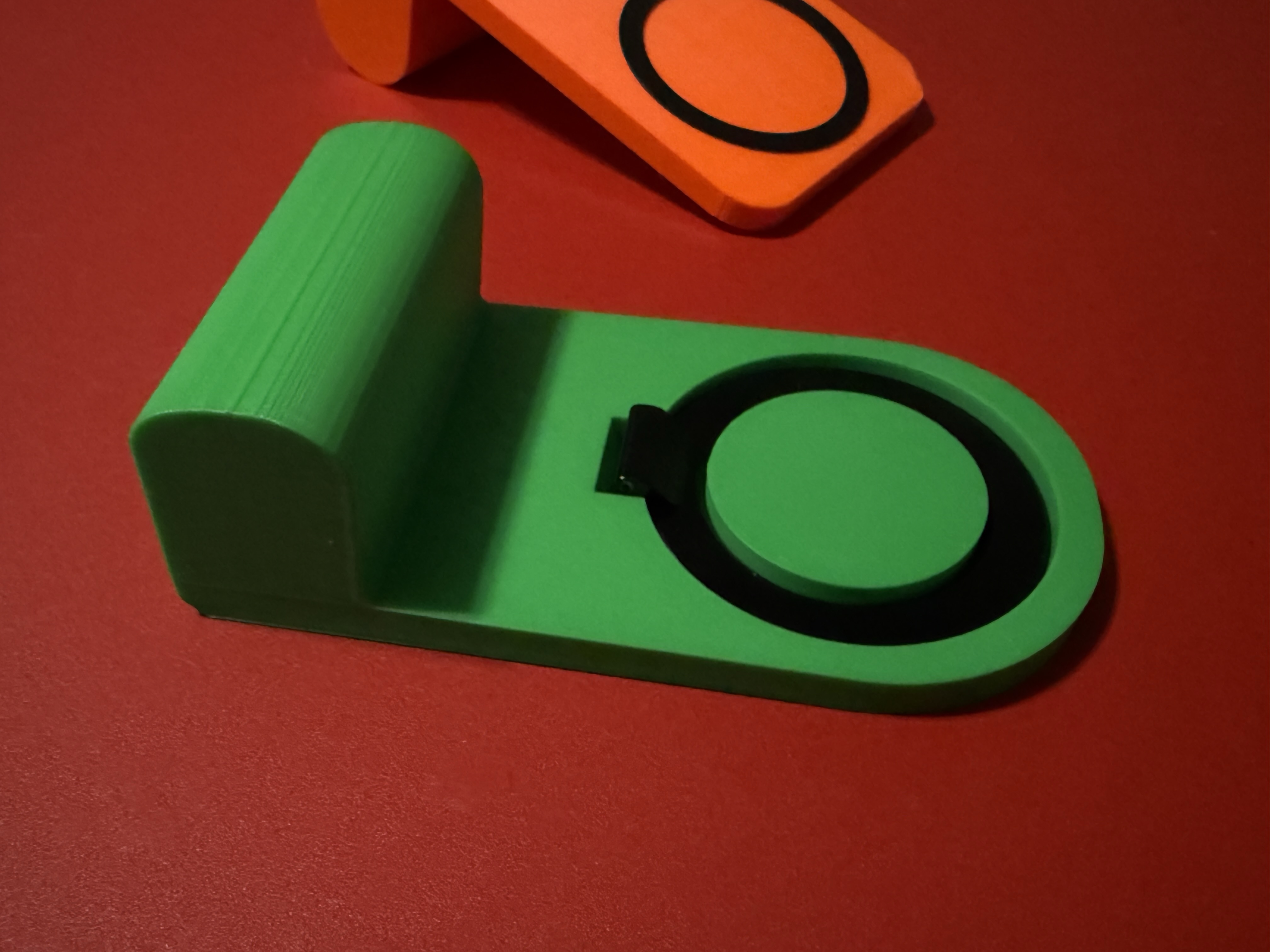

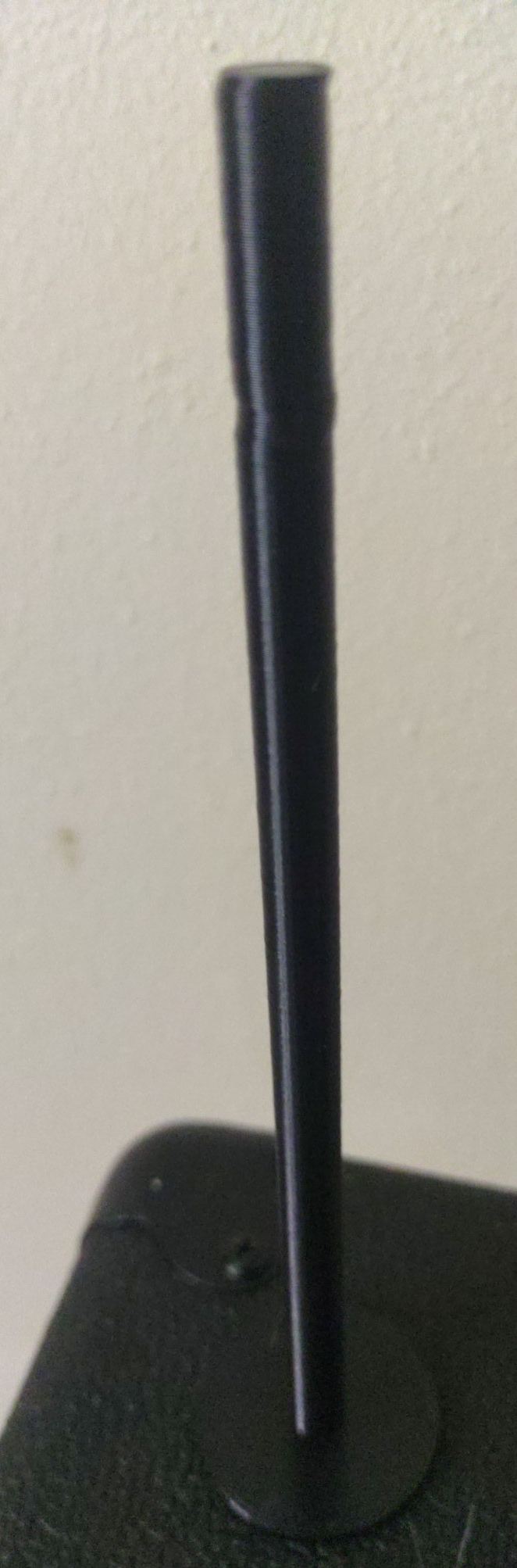

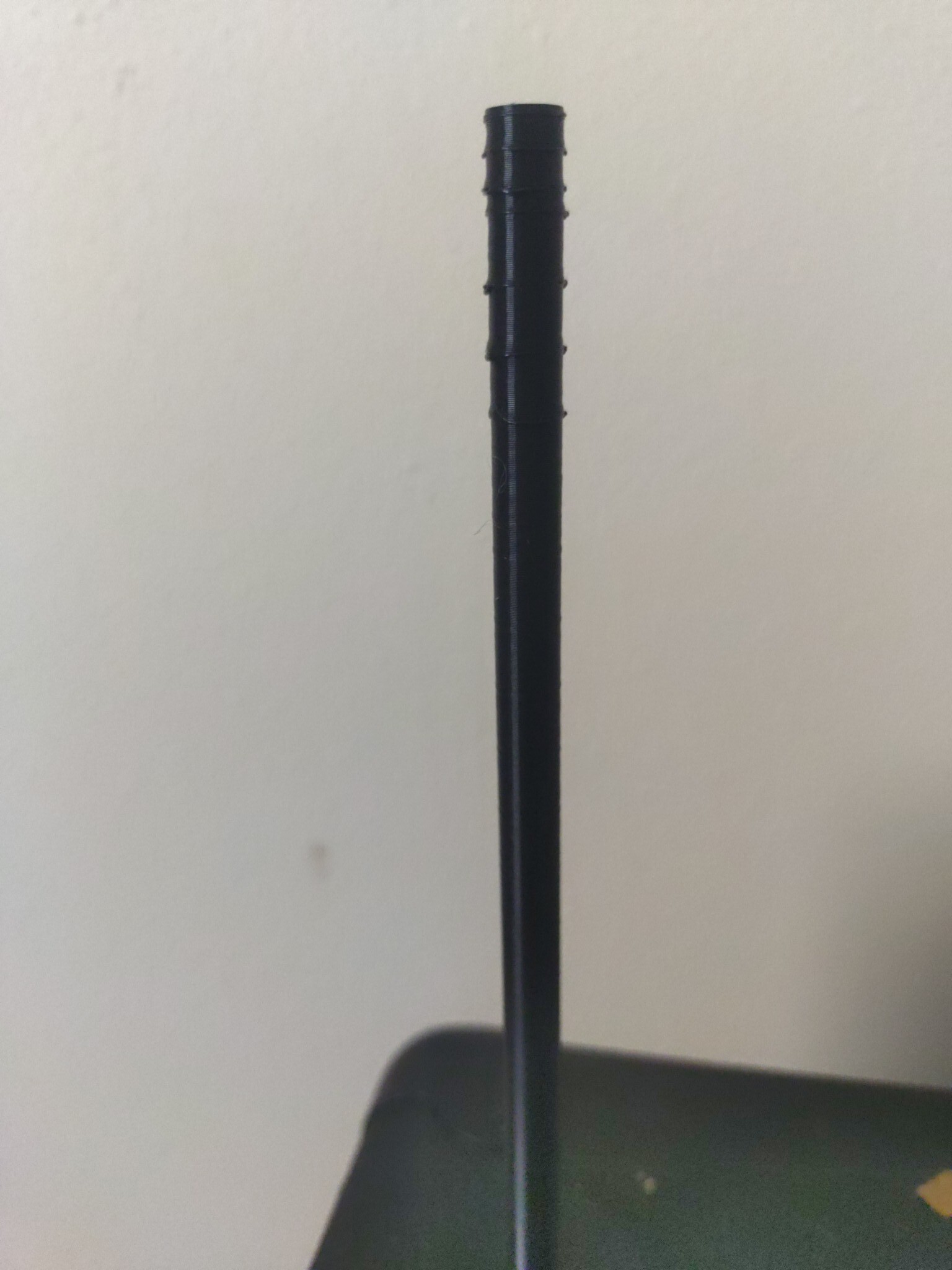

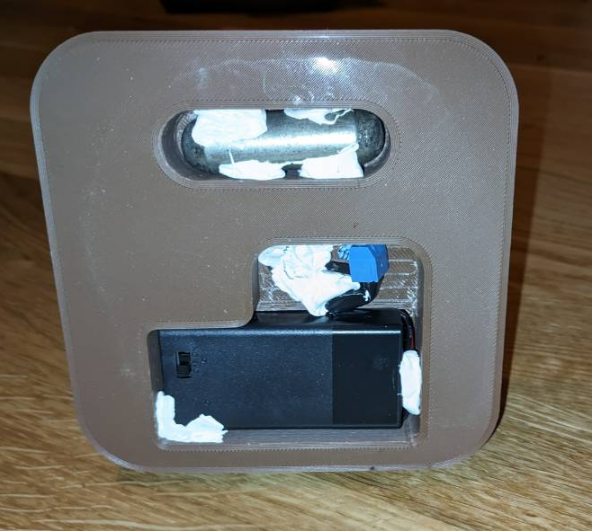

Designed this coaster, because I wanted something tidy looking and dual color, without filament changes

(media.printables.com)

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

119

45

46

47

48

49

50