21

7

Into sewing? Here's a giant map of secondhand fabric stores by city! (USA & Canada)

(www.sewingthroughfog.com)

view more: next ›

Sewing, Repairing and Reducing Waste

1090 readers

1 users here now

A place to share ideas, knowledge and creations with textiles. The focus is on reducing waste, whether that be sewing from the scraps left from other projects, using the end of rolls and remnants, or repairing and remaking finished pieces.

founded 1 year ago

MODERATORS

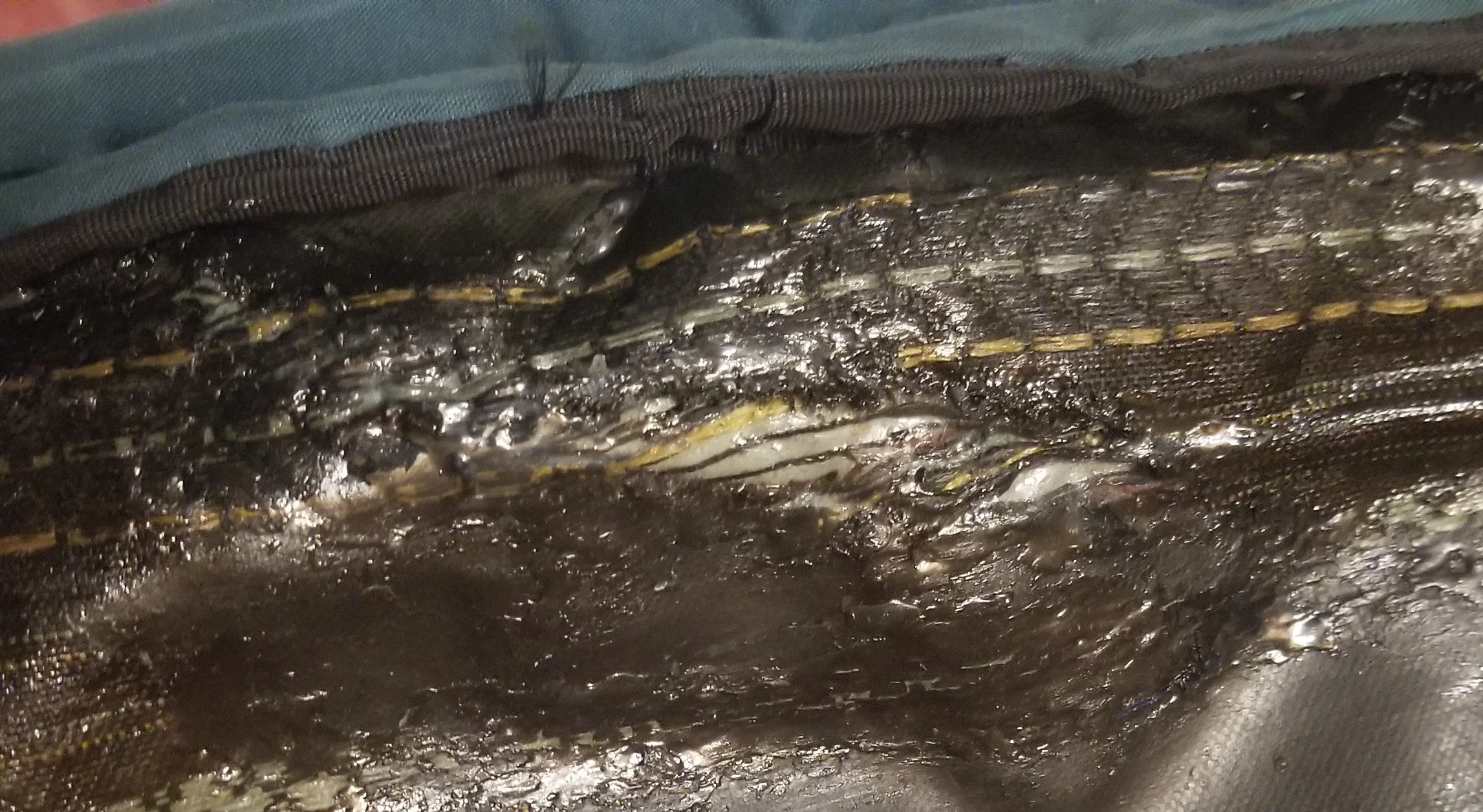

Sewed some of the smaller rips, then added repair tape to the largest one:

Sewed some of the smaller rips, then added repair tape to the largest one:

Then sewed the rip itself with fishing line (the strongest thing I could think of to hold the weight of the bag's contents, plus I just happened to have it at home:

Then sewed the rip itself with fishing line (the strongest thing I could think of to hold the weight of the bag's contents, plus I just happened to have it at home: