Torx is the only head that needs to exist. The rest can go fuck a rusty chainsaw.

196

Be sure to follow the rule before you head out.

Rule: You must post before you leave.

Other rules

Behavior rules:

- No bigotry (transphobia, racism, etc…)

- No genocide denial

- No support for authoritarian behaviour (incl. Tankies)

- No namecalling

- Accounts from lemmygrad.ml, threads.net, or hexbear.net are held to higher standards

- Other things seen as cleary bad

Posting rules:

- No AI generated content (DALL-E etc…)

- No advertisements

- No gore / violence

- Mutual aid posts are not allowed

NSFW: NSFW content is permitted but it must be tagged and have content warnings. Anything that doesn't adhere to this will be removed. Content warnings should be added like: [penis], [explicit description of sex]. Non-sexualized breasts of any gender are not considered inappropriate and therefore do not need to be blurred/tagged.

If you have any questions, feel free to contact us on our matrix channel or email.

Other 196's:

Square is really good too.

Phillips and flat head bits fit in a variety of sizes of screw heads. We seem to have chosen convenience over performance.

If memory serves me correctly square drive is patented, & thus requires licensing, which is why it's less commonly used.

This is the way. Also I'm new to Lemmy so forever will this be how I start my experience here.

Torx is hands down better in every way than flathead and Phillips.

phillips worst screw self stripping garbage

That is actually a feature of this design. They were the answer to in-line screwdrivers who had no precise stopping torque: cam-out before the thread is damaged.

I know it's an intentional feature, but it's a bad feature. Camming out damages the head of the screw. This exchanges repairability for manufacturing simplicity. Additionally, the sloped shape makes it possible to use slightly oversized or undersized drivers, further increasing the chance of camming out and damaging the screwhead.

The torx are the most resistant, the rest can also cease to exist.

Anyone who willfully uses a slotted screw on a new project in the presence of even somewhat reasonable alternatives should have a lifetime ban on designing any items for anyone.

Also, use Robertsons, gink.

it’s single valid use: somewhere that you may not have tools but might require an impromptu fix… preferably paired with a much larger screw than technically required so you can use things like coins as a driver

Yeah, like mounting plates for cameras…. Um, I think that’s the only place I’ve appreciated a slot screw

Sewing machine too! Always using scissors to open that slot screw to change the needle

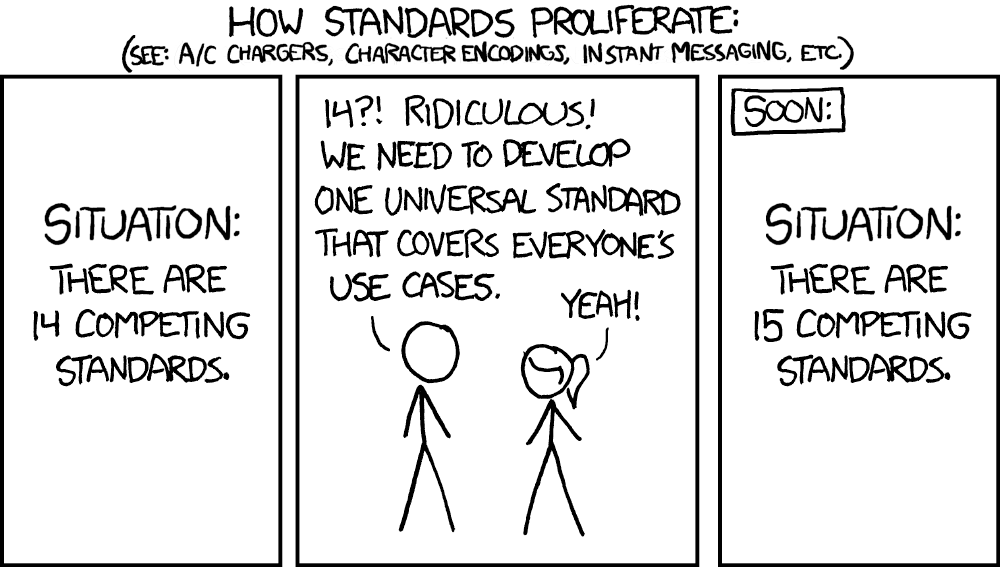

Situation: There are 20 screw standards.

John Corporate: "20 standards... I know, I'll create a new type of screw that will be unique to my corporate overlords and prevent users from repairing their own devices!"

Situation: There are 21 screw standards.

Relevant xkcd:

To be fair, UTF-8 did win the character encoding wars. Kudos to the Unicode designers I guess.

Wish Windows knew that

My favorite is hex, self centering and doesn't strip easily

Torx are the better hex as they apply torque to six planes, not six lines. It's right-out impossible to strip a torx.

The disadvantage is that it's harder to machine but that really doesn't matter for cast screws. Tools are also cheaper that's why IKEA etc. use them.

Square is called a Robertson and is the standard for construction in Canada. None of that bullshit Phillips trash.

The real "actual screw".

I strongly dislike how many times I've stripped a Phillips and used a die grinder to force it to become a flat. Torx is fine.

I used to restore "barn bikes", most of them were Japanese. It took me a while to figure out the difference between Japanese Industrial Standard (JIS) and Phillips screws. Of course over the years, a lot of the fasteners had already been cammed out by previous owners using a Phillips screwdriver in a JIS screw. I had to resort to the die grinder method far more than I'd have preferred.

Canadian here. I'm offended the Robertson (square) has been shamed like this.

Robertson head gang represent. It's just so good.

I hate phillips. It seems like their only purpose for existing is to strip out so that you can never remove them.

Personally, any time I have a project, I always opt for torx (star). The screwdriver bits for them are not tapered so they don't push themselves back out of the screw-head (unlike phillips), so they tend to stay in place and grip much better. It's a lot harder to screw up a torx screw or bit than a phillips one.

Hex screws are sick tho. Great when there isnt much space to tighten regular screws.

Robertson, hex and torx should be on that list, the rest of that shit can stay in the scrap bin of designs

I like pluses and squares. Minuses need to be removed from existence

Minus is great because you can use a butter knife on a pinch to unscrew/screw it

Square drive on personal projects, forever and always. Maybe I'm buying the wrong torx, Phillips, and flat screws, but they strip out way too often. I've never had issues with square drive screws no matter where or how I use them

Americans will do anything the hardest way possible, huh lol

Robbie superiority.

Square is my favorite but never used in industrial maintenance much. The square combos are on new electrical devices for construction though. I use mostly Phillips/slotted. A few security torx. Lots of hex heads, and all the small electrical terminals are slotted.

Sadly, some of the more exotic ones have been used to dissuade third-party repair. Some repair shops have been on a mission to replace iPhone screws with more common standards to facilitate general access.

We stan Phillips/slot

Phillips/slot: the pansexual of screwheads

6-lobe is life. I got a box of them for a set of stairs I had to rebuild, and the sheer ease of use makes me never want to go back.

Triangle, but with bevels. I believe old McDolan toys had those

Also, why has Python its own screws?

Anything that is compatible with slotted or phillips is fine.